Today, we have great news – we have just installed a new press brake from the renowned company Prima Power! This advanced machine increases our productivity and precision while allowing us to operate responsibly and efficiently in sheet metal bending.

.jpg)

.jpg)

Prima Power eP1030: Practical Efficiency Meets Responsible Operation

Today’s manufacturing environment demands reliable performance, precise results, and responsible resource use. The eP1030 press brake from Prima Power addresses these requirements head-on. Thanks to its servo-electric drive, energy consumption is reduced, hydraulic oil is unnecessary, and maintenance costs decrease. The result is a greener operation with lower operational costs.

Easy-to-use programming combined with exceptional accuracy helps us minimize defects and reduce material waste. In short:higher-quality sheet metal components produced more efficiently and cost-effectively.

.jpg)

Speed, Precision, and Safety Combined

The eP series press brakes feature high acceleration and deceleration, delivering an exceptionally fast response from the servo-electric drive. Compared to traditional hydraulic presses, the eP1030 allows for significantly shorter cycle times – up to 30% or more. This results in a considerable boost in productivity without sacrificing quality.

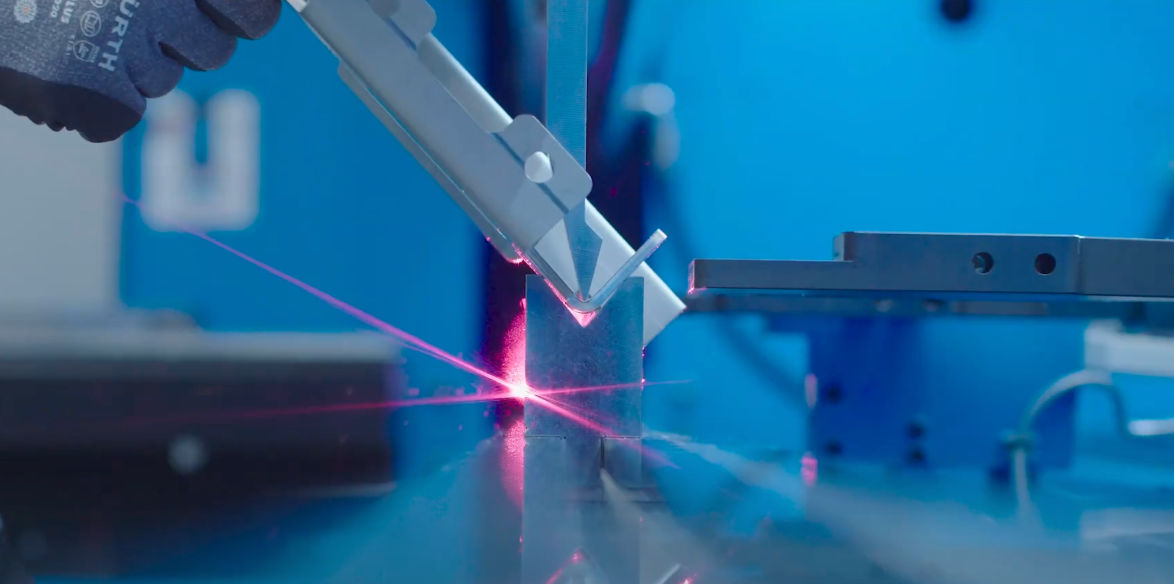

Users can precisely set optimal bending parameters with programmable working speed to ensure perfect accuracy and maximum operator safety. The Lazer Safe IRIS system further enhances this, facilitating achieving high working speeds while minimizing the risk of accidents.

.jpg)

Technical Specifications and Flexibility

The eP1030 press brake is part of a broader range of machines that cover a wide spectrum of manufacturing needs. It is available in several versions depending on production requirements:

- Press force 100 tons

- Bending table length 3000 mm