At ALFA3, we understand that each atypical project has its own character and requires a unique approach. Thanks to our specialization in designing and manufacturing bespoke products, we can offer solutions that match your expectations. With a wealth of experience, expertise, and the use of cutting-edge technology, we create products that help you maintain and grow your competitive advantage.

Consultation and identification of needs

Every partnership with ALFA3 begins with a detailed consultation, during which we focus on thoroughly understanding your needs and requirements. This initial phase is crucial to the project's success as it helps us define your exact expectations and key product parameters.

We will be happy to advise you on a suitable solution.

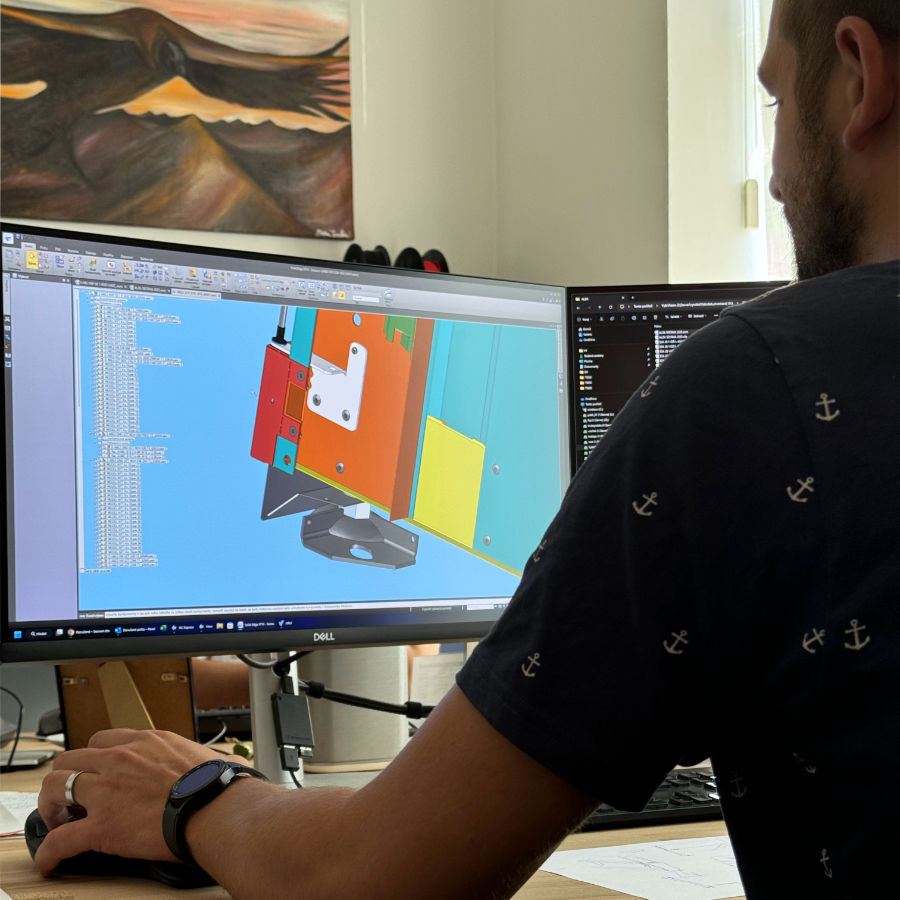

Design and iterative development

After the initial consultation, we move on to the design of the solution. At this stage, we work closely with you to create a concept that meets your requirements. Our method is iterative, which means we continually adjust and refine the design based on your feedback until we find the optimal solution.

Production, testing, and delivery

Once the design is accepted, we start the manufacturing process. Our state-of-the-art technology allows us to execute projects with the utmost precision and high quality. Throughout the production process, as well as after completion, we carry out thorough checks to ensure that all the specified requirements are met.

Technological background

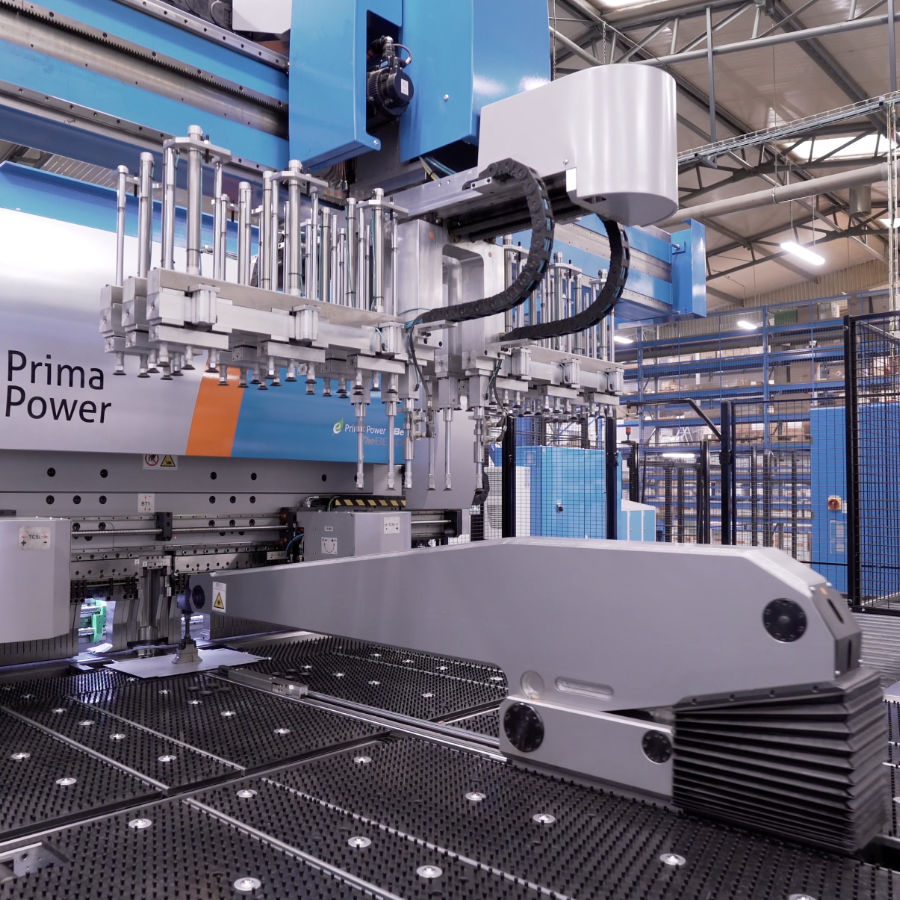

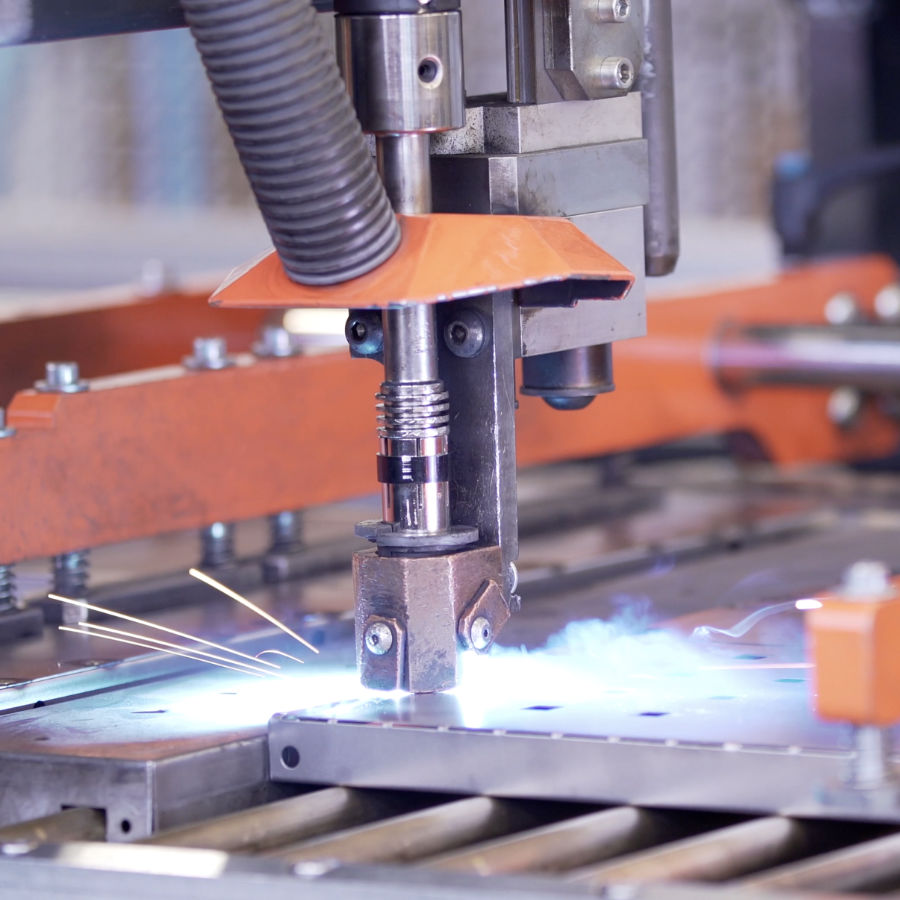

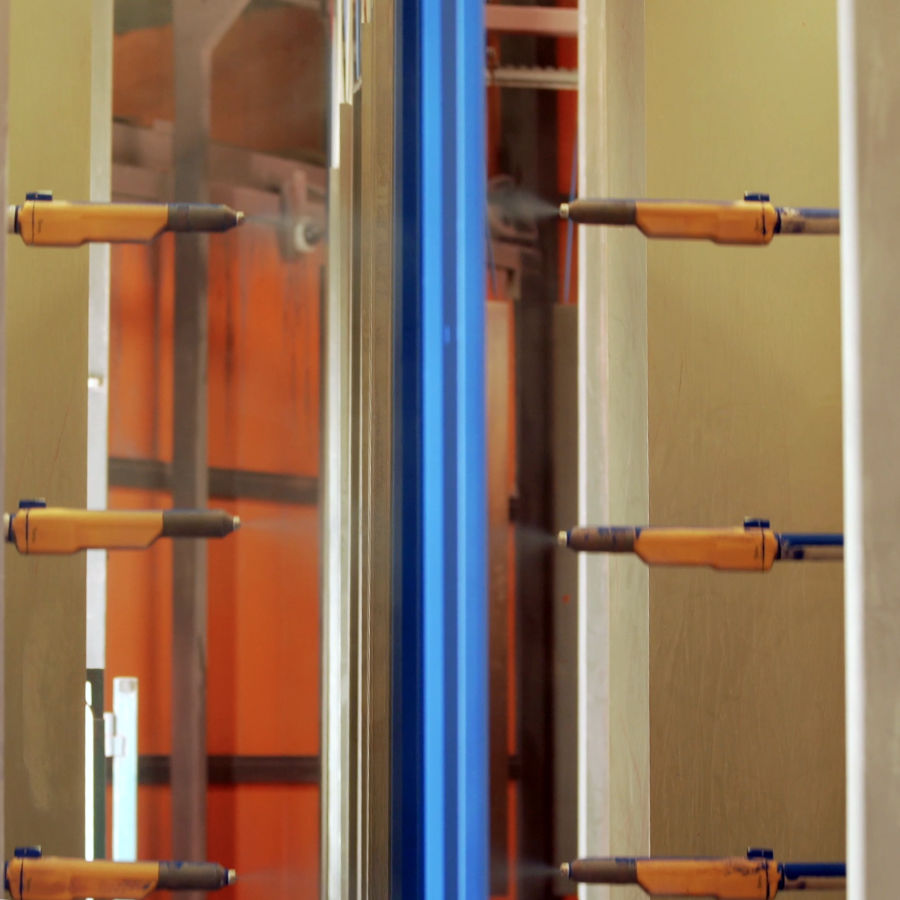

At ALFA3, we have a wide range of advanced manufacturing technologies that allow us to create customized products with maximum precision and efficiency.

List of technologies

- Automated robotic production lines Prima Power PSBB with punching and shearing machines SBe and panel benders EBe connected to automated warehouse NT,

- CNC punching equipment TruPunch,

- Prima Power servo-electric bending presses of the eP series

- Semi-automatic panel bender FBe

- Resistance and MIG/MAG welding technologies, manual and robotic,

- Painting line IDEAL LINE with semi-automatic application technology GEMA Magic Cylinder II,

- Assembly and packaging technology.

The Case Studies

Our results speak for themselves. Throughout our business, we have completed several successful projects that have helped our clients achieve their goals. We are happy to share case studies that show how our solutions have been able to meet specific customer needs and deliver results.

References and feedback

Customer satisfaction is our priority and we value their feedback very much. Testimonials from our clients are a recognition of our work, and a valuable source of information for us to further improvement our services. Thanks to this feedback, we are continuously upgrading our processes and technology to offer you even better products.